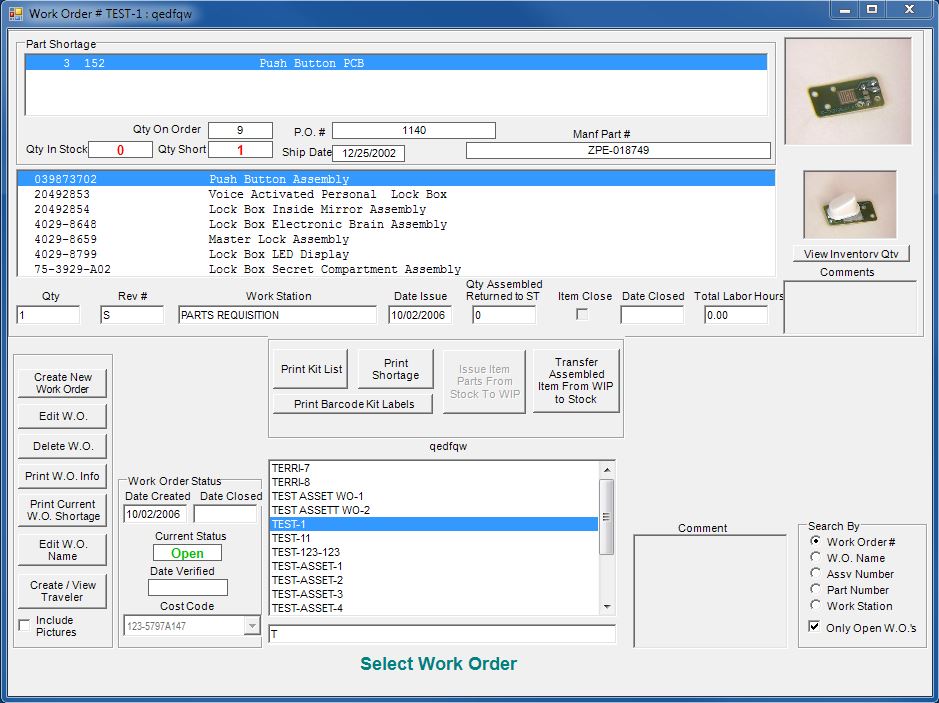

Issue all Items With a Work order

The Manufacturing Work Order is used to Issue all the Inventory Items required to build an assembly.

This Software screen will display the shortage information along with the current Purchase due date

Several Assemblies can be placed in a single work order.

The basic steps are :

1. Create the work order

2. Select the assemblies needed to construct

3. Issue the inventory parts from the stockroom

4. Observe the inventory shortages and notify the purchasing department.

Once the items have been received, the software will highlight the item in the shortage list

and prompt the user to issue it to the assembly floor.

The Software can print a kit list and barcode kit list labels, which makes it easy for the warehouse personal to pick the kit.

The software first decrements inventory stock quantity and then logs the shortages that were found.

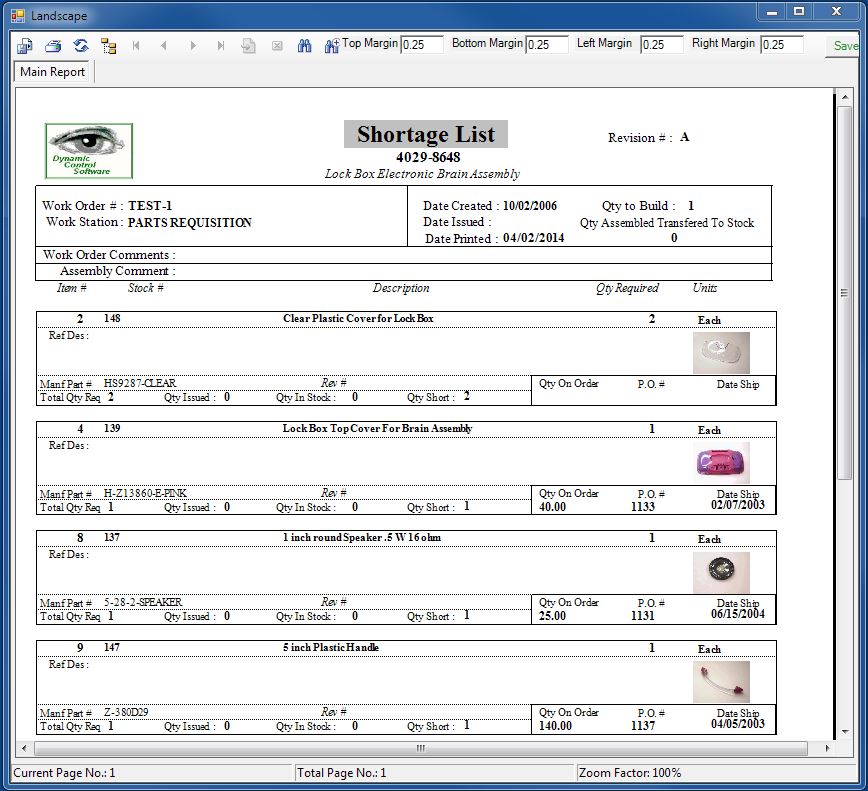

A Shortage report can be printed from the 'Workorder' screen after the the assembly parts have been issued to W.I.P (Work in Progress).

The report contains all the information needed to expedite the order placement of the inventory items

along with the specific work station that is in need of the part.

The manufacturing shortage report also informs the user if the inventory part is currently on order, what the purchase's order number is and the date that it is due into the warehouse.

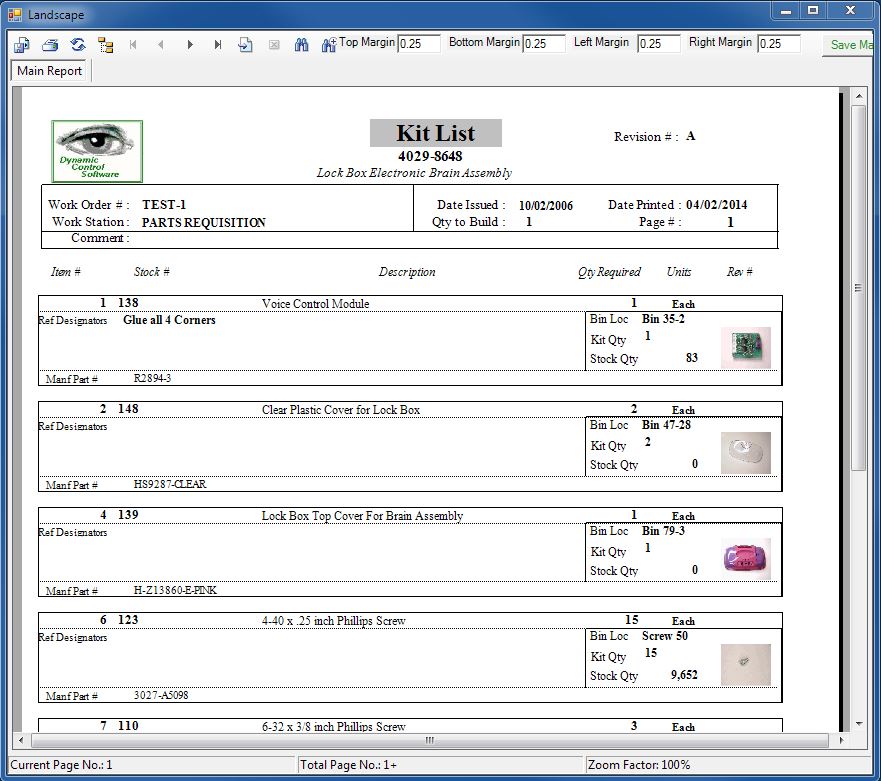

The 'Work Order Software' screen can also print an inventory kit list report that contains the parts required to build the assembly.

This information includes the inventory stock number , work order number , work station , kit quantity and the stockroom bin location.

This report can be use by the warehouse personal to collect the items from the bins.

Barcode kit labels are a huge benefit

to the stockroom and manufacturing floor personal.

Using a barcode label program, the inventory software can generate

detailed assembly kit labels.

These labels can be used to mark individual kit bags.

The label contains the kit quantity , assembly number, and the quantity per assembly.

The barcode can be used to requisition more from the inventory in case of loss or breakage.

The assembly floor personal can bring the bag to the warehouse instead of writing the stock number and avoid possible errors.

With the picture on the bag

label the warehouse personal can verify the part that is in the stock bin is the correct part for the kit.